MILK Factory – Success Story with SMF machines

SMF bottling lines – solutions for milk and dairy products

SMF main area of activity since 25 years is production of PET blowing machines, conveyors and delivery of complete filling lines. In recent years we can see growing role of PET bottles as packaging for milk product. Currently we see that ESL milk filling into PET bottles is strategic option for dairies in Europe.

ESL (Extended Shelf Life) Milk

ESL (Extended Shelf Life) Milk is fresh milk with an extended shelf life up to 21-28 days but also with ESL 2 standard – up to 90 days (days in cold chain). Different than UHT sterilized at a higher temperature, quality of ESL milk is reached by the combination of microfiltration (to reduces the bacterial load of milk by mechanical separation) and low-temperature short-time pasteurization as well as high level of hygienic standards on the filling line (ULTRA CLEAN technology).

ESL provides minimum nutritional loss – Lactulose and furosine content is low compared to UHT milk and less denaturation of α-lactalbumin and β-lactoglobulin in ESL Compliance with these requirements yields ensuring also that the milk has very natural taste.

PET Bottle for Milk – Cost effective

PET bottle is also one of the cost-effective solutions for packing for milk. The weight of the PET bottle is substantially lower than HDPE (22 g for 1L PET bottle) . PET packing lines have low scrap rates as well as bottle productions itself runs without plastic waste (like cutting HDPE scrap).

Lower costs is reach thank to material saving and low power consumption of the complete filling line. PET is extremely lightweight and has a high shock-resistance (non-fragile) so it’s convenient for distribution (transport in several layers is possible).

The PET bottle for Milk is an interesting solution for the target customer

PET bottle is also very convenient and attractive for the customer. Bottles are esthetic and can be tailor-made with original, individual shapes. PET bottles can be transparent or any other colour including white. Cap closure dedicated for PET allows the multiple use (repeated opening and closing) without risk of leaking. Neck of the bottle is without any sharp edges – convenient to drink directly from the bottle. Like glass, PET is a biologically inert material that doesn’t react with beverages or foodstuff and is resistant to attack by micro-organisms. PET bottles, different than carton packaging, can be easily recycled because it is 100% plastic without any paper or aluminum additives.

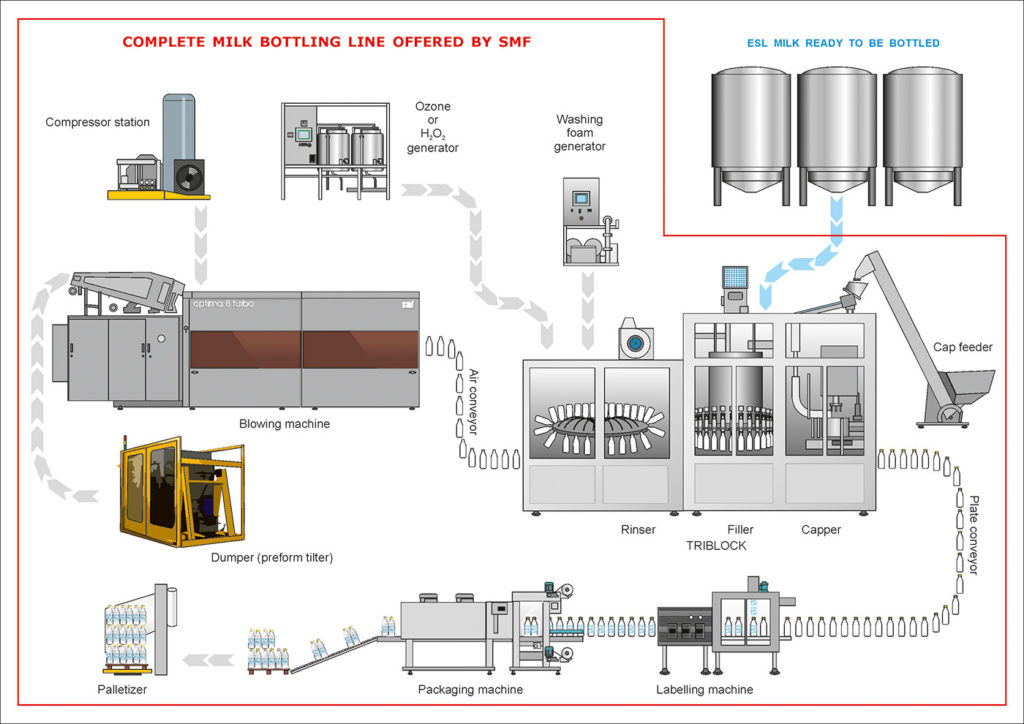

Elements of classic blowing and filling line for milk in PET

Key elements of classic blowing and filling line for milk in PET – entry level 2000-3000 BPH for 1L and medium-sized outputs 6000-7000 BPH of 1L or 10 000 – 12 000 BPH of 1L:

- PET bottles automatic blowing machine – ultra clean version with overpressure inside the machine

- System of empty bottles conveyors HEPA filters on fans

- Triblock ( rinser with option to use ozone water&filler with option inside foaming and UV-treatment of caps)

- System of full bottles conveyors – plate conveyors

- Labeling machine OPP – hot-melt or sleeve type

- Group packaging – shrink-wrapping or carton packer

- Palletizer –optional

Optionally, blowing part can be connected directly with filling parts and work as SynchroBlock without air conveyor between machines.

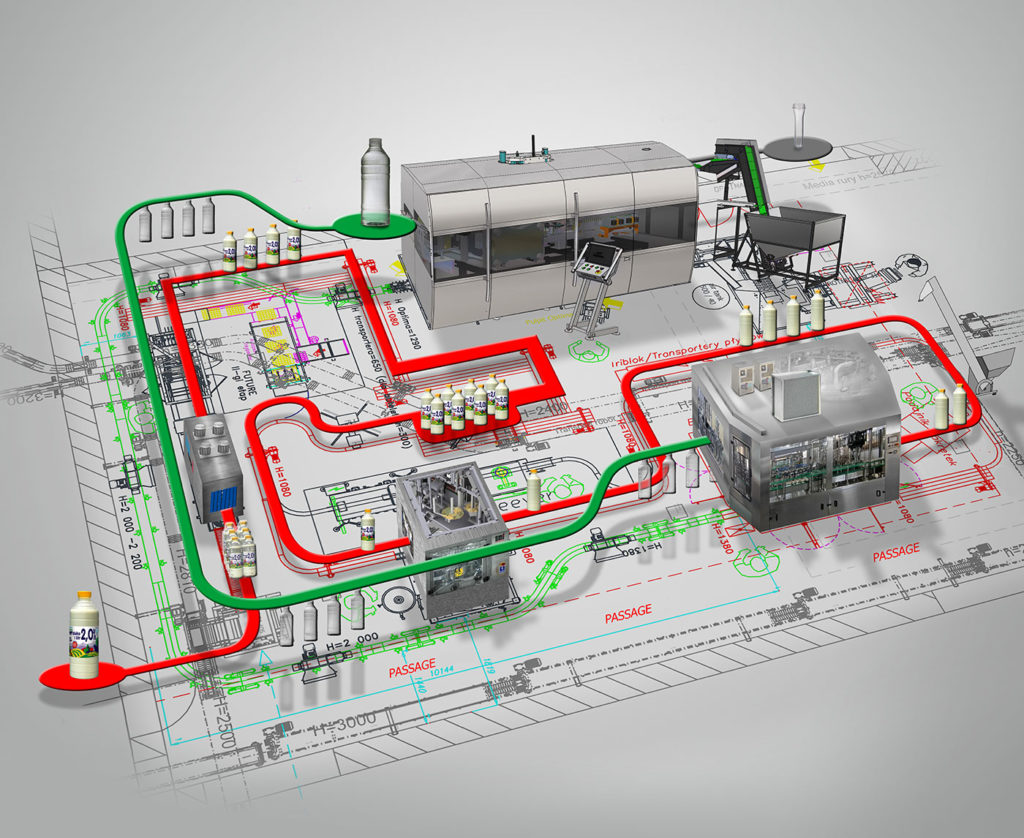

PET bottling line for milk in Poland

One of the first SMF “MILK customer” for PET blowing machine was milk company located in South- East of Poland. The history of our cooperation began with the first automatic SMF machines from the combi series. The Combi 400 was delivered in 2007 and only after one year was ex-change for the machine with higher speed – HS 6000 which can work 5 000 BPH of 1L – this machine is still in use. Change into PET was right decision and milk in PET turn out to be desirable product.

Company used this market opportunity and in 2013 has started up new line for milk product (yogurts, kefirs) – 10 000 BPH with Optima 7 PET blowing machine. Consumption of the milk was still growing as well as number of customers choosing PET bottle as preferable packaging for milk product. With grow of the customer’s awareness and visibletrend for natural food, our client has started investigate other options to increase market share and was one of the first company in Poland with ESL milk line. Since 2016 in this dairy factory works ESL milk line for 10 000 BPH for 1L bottle with optima 8 turbo. This is a story about two companies that grown together and together increased their production capabilities.

The linear engineered Optima Turbo Series includes two, four and cavity machine with an output of 7200 bph; an eight-cavity version with 14,000 bph capacity.

SMF PET blowing machines

The series is designed to be fully electric and is effectively supported by PLC and nine servo drives At the same time, the series strives to be energy-efficient, with a specially-designed NIR heating process in place of conventional IR ovens. In addition, the oven’s compact design is intended to minimize space requirements at the production level. The Optima Turbo Series features a central system for lubricant provision, facilitates rapid mould changeover and reduced air consumption for the blowing. Finished bottles are transported by air conveyor directly to the filling machine.

Ultra clean version of Optima Turbo

Ultra clean version of Optima Turbo – specially designed for milk factory – additionally includes top cover on the machine (roof) to ensure cleanliness inside the machine together with fan mounted on the top.

Thanks to the over-pressure inside the machine, the dust from outside doesn’t come inside the machine (with air filter to ensure that incoming air is free from the dust). At the top of preform feeder UV LAMPS ensure disinfection of preforms and necks of the bottles. During production stops, the interior of the machine is filledwith ozonized air to reduce numbers of bacteria and stop theirs grown.

Additionally ionized air is injected during preform movement on the gravity rails before heating and blowing process (generate negative ions protects against dust). Also preform hopper is covered so preforms are protected against contamination and reducing dust exposure.

Microbiological purity of the milk and high hygienic conditions ensured on SMF milk lines, results in quality products, with high nutrition values and grate taste – features valued by consumers& market.