Manufacturing of surgical masks at scale, meeting the ever-increasing demand for masks, cutting down costs, and increasing productivity: These are what you’re going to get with SMF’s mask-making machine! Using the latest manufacturing technologies and being fully compliant with EU standards, these are machines you can truly rely on!

Surgical Mask-Making Machines

Our MPL-100 is a fully automatic system for protective mask production from spunbond 100% polypropylene texture 15-26g/m2. This system is suitable for 2-3 or 4-layer mask production, with the possibility to also apply a filter. Depending on the number of layers, our machines can reach a continuous output of 80 to 100 masks per minute.

All vital units for the mask production process are controlled by Festo vales and steered by a Mitsubishi PLC. The MPL-100 not only guarantees precision during mask production, but it also allows you full control of the production process allowing you to customize it to your company’s needs.

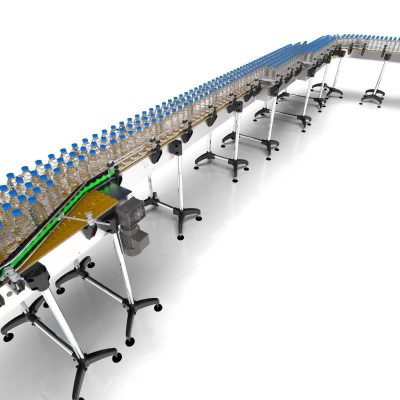

Mask Production Line

The entire mask production process is fully automatic with no sewing or glue required. With the ability to control the number of protective layers, the option to use filters, and the size of the masks, our surgical mask machine allows for the production of a wide range of masks with varying degrees of protection, production costs, and applications. This versatility gives you full control over the mask-making machine, and by extension, the production process making our MPL-100 suitable for companies of all sizes and needs.

Medical Mask Machine FAQ

What Is the Cost of a Surgical Face Mask Machine?

The cost of a mask-making machine will vary a lot depending on its size, features, speed, capacity, and more. At SMF, we design custom solutions for our clients, and our costs scale with their needs, and that’s how we make sure our offers are extremely cost-effective. Get in touch!

How Do You Manufacture Medical Face Masks?

The production process is divided into two main stages. In the first stage, the initial mask-forming material is cut to the pre-programmed dimensions, it is then folded, and lastly, the mask is welded. In this stage also metal clips are added to the top part of the mask so the shape of the mask can accommodate the shape of the nose. During the second stage, two elastic bands are welded on both sides of the protective mask to allow the mask to be attached to the ears.

Reviews

There are no reviews yet.