Unique Unscrambler Machine Solutions for Bottling Lines

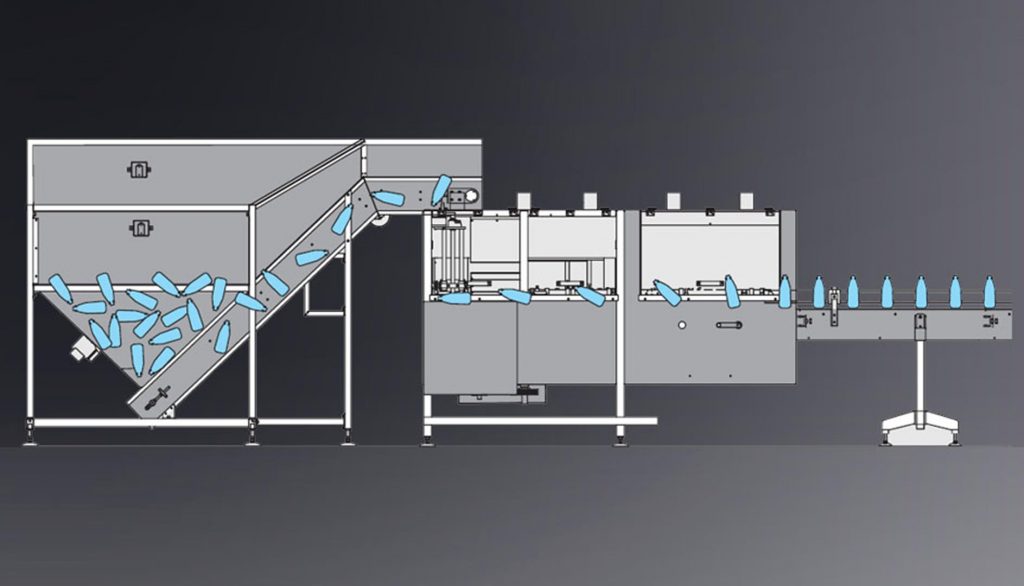

At SMF, we offer liner “belt type” unscramblers (SB6 and SB10) as well as the “pocket type” rotary unscrambler SB20. Our machines can handle bottles of various capacities from as small as 100 ml to as large as 2 liters. They are capable of processing up to 12,000 bottles in an hour. This makes them capable of meeting the needs of the most demanding bottle filling lines.

Our machines use cutting-edge technologies to reliably unscramble the bottles and put them into the feeding lines. They carefully handle the bottles and prevent deformations. They require little maintenance and perform the job with little to no oversight. And lastly, every automatic bottle unscrambler we create works perfectly well with different types of bottling lines, including the ones created by SMF.

SMF unscramblers special pharma version

SMF unscramblers can be produced in a special pharma version. The parma versions of our machines have all contact parts made of stainless steel, are fully sterilized to protect against contamination, and can be equipped with a system for ionized air rinses.

These qualities make our bottle unscramblers perfect for use in pharmaceutical industries. Whether it is medicine or cleaning agents, our bottling systems are capable of handling the task.

Key Advantages of SMF’s SB Series

When you buy an SMF unscrambler, you’re not just getting any typical unscrambler. Our SB line offers a range of unique advantages that you definitely can’t miss out on:

- Suitable for PET bottles or bottles made of other types of plastic.

- Our SB unscrambler line is very versatile in handling bottles of various sizes and shapes: Our machines successfully unscramble cylinders, jars, ovals, squares, rectangles, and other oddly shaped bottles.

- It is a cost-effective solution: Our unscrambler line requires little maintenance and allows for the automation of the production process, which improves productivity and cuts down on costs.

- Hygienic: bottles do not have to come in contact with operators and can be handled entirely by machines, which reduces the risk of contamination. Additionally, all bottle contact parts of our systems are made of stainless steel and plastic and can be sterilized for added safety.

- Operational simplicity: No specialized personnel is needed. Fast and easy format change makes operations smooth and seamless.

- All guard doors are provided with approved safety interlock switches.

If these advantages sound good to you, then you should give us a call. At SMF, we help design customized solutions for our clients. If you need changes made to our SB unscrambler line to better suit your business needs, our talented team of engineers and designers is more than ready to take on the job.

What is a Bottle Unscrambling Machine

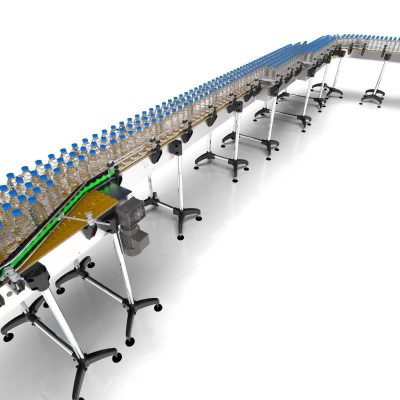

In the bottling industry, a bottle unscrambler is a device used to feed bottles onto bottling lines automatically minimizing the need for human labor. Bottle unscramblers come in a variety of designs, but they all serve the same purpose: Feeding bottles at fast rates automatically eliminates the costly, ineffective manual labor usually involved in this process.

Since containers are tossed at random into a large hopper that may hold hundreds of bottles, bottle unscramblers receive the bottles in these unorganized, random positions. Unscrambling machines are designed to put the bottles into an upright position. Bottles in an upright position can be transferred to the bottle filler, followed by a capper, a labeler, and the remainder of the filling line.

This makes bottle unscramblers the first and key part of the bottling process. If the bottle unscrambling machine doesn’t work correctly or efficiently, your whole bottling system will break down. This is why at SMF, we make sure the bottle unscramblers we design are highly reliable and efficient.

Reviews

There are no reviews yet.