Description

Etima

ETIMA is a family of automatic hot glue rotary labelling machines suitable to apply labels on the PET, glass bottles, metal can and other types of the plastic containers. These machines are designed for applying wrap around or partial roll-fed labels form OPP, paper or other material like PET/ /polystyrene/ polypap labels. Thanks to the 3 different technologies of controlling platform rotations, Etima can handle not only standard cylindrical and shaped containers but also can be used for the applications that require orientation so the label will align with the front of the bottle.

Versatility, Flexibility , Precision of SMF roll-feed label application

The working speed varies according to the container diameter and volume so the number of the platforms can be 9, 12 or 18. For standard small cylindrical containers, Etima working speed is ca. 15 000bph (with 9 platforms), up to 38 000 bph (with 18 platforms version). SMF labelling machines can be adjusted to the container with the diameter from 45mm up to 170mm, which allows to offer solutions for labeling the wide range of bottles: from 200ml up to 6L. SMF Labelling machine can be installed before and after filling: the label can be applied not only on filled bottles but also on the empty bottles (option).

Modern & durable design

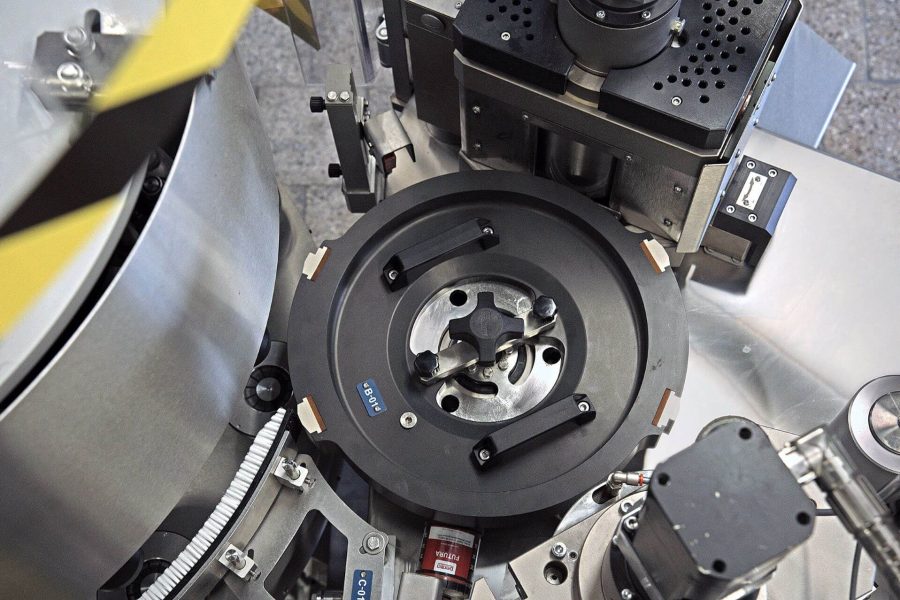

Etima labelling machine is based on servomotor technology – all crucial machine units are powered by minimum 11 servo drives : feed screw ,infeed & outfeed starwheel , the carrousel, bottle platforms with belt system, , roll-feed on label stations , cutting system drum, moves of the glue roll, transfer drum and also to moves the roll which delivers labels on the cutting drum. All traditional inter-axis gears, chains, cardan shafts and belt transmissions were replaced by most effective & reliable solutions – OMRON servodrives. Each rotary shaft of ETIMA labelling machine is controlled by its own servomotors directly mounted on the axe. Thanks to elimination of the mechanical transmission, SMF labeller is more durable & precise and maintenance costs as well as energy consumption is significantly reduced.

Compact and ergonomic layout

Design of Etima labelling machine allows easy access for format change (only 15 minutes!) or maintenance as well as is suitable for fast and effective cleaning procedure. All contact parts are made of stainless steel, aluminium or other non-corroding materials which high hygienic conditions. Installation and transport of Etima machine is very simple because Etima is built (and packed in) only of two modules – labelling station and labelling carousel. These modules are connected with 2 multipin plugs with cables.

ETIMA KEY FEATURES

- Working speed form ca. 15 000bph (with 9 platforms), up to 38 000 bph (with 18 platforms version) with 500ml bottle, suitable for bottles from 200ml up to 6L.

- Able to work with many types of containers – Etima can apply labels on PET, glass, metal (cans) and cylindrical or shaped containers.

- Designed for applying wrap around or partial roll-fed labels made of polypropylene/polystyrene/ paper and polypap label.

- Precise label aplication even on square or irregular containers – thanks to advanced & various types of platform and bottles positions control.

- Available in many layouts configurations – linear (standard) with 2 star-wheels or optional: angle 90 (L configuration with 3 or 4 star-wheels) or parallel ( U configuration with 3 or 4 star-wheels) as well as clockwise or anti-clockwise.

- Easy access for inspection, maintenance, format change, cleaning procedures – visual control thanks to transparent panels on the top of the machine and location of the electric cabinet underneath the labeling station ( transparent lower guarding panels available as an option).

- Easy for transport and installation – only 2 main parts- frame and carousel.

- User friendly – PLC with different access levels and very easy & fast format change in ca. 15 minutes – without any special tools.

- All drives moved by dedicated servomotor – greater accuracy of the labeling placement, better control and adjustments of the machine, fast detection of any collisions and problems, significant reduction of wearing parts – trouble free operation and reduction of the maintenance costs and power consumption.

- Low glue consumption with micrometric glue aplication– even 200.000 bottles with 1 kg of glue in ambient temperature for 100 mm label height.

- Long use of the blades – even 300 million cuts, easy change and precise blade adjustments.

- Cost-saving labeling – Etima can handle OPP labels with only 20mircons thickness OPP and even 18mm width.

- Possibility to apply label on empty bottle (optional with pressuring jacks ) – labelling machine can be installed before and after filling.

- Equipped with internet module for easy on-line technical support

- Auto – splicing system for labels rolls available as option

Additional information

| Color | Red |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.