Transport empty bottles machine

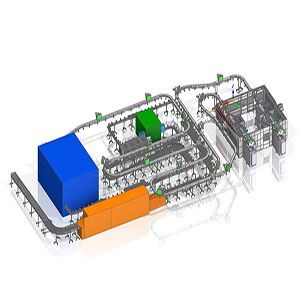

The air conveyor (pneumatic conveyor) is used to transport empty bottles between machines working on one filling line as well as to buffer the bottles enabling automatic operation of the line. Most often they are used to transport an empty PET bottle from the blowing machine to the filling machine (filler).

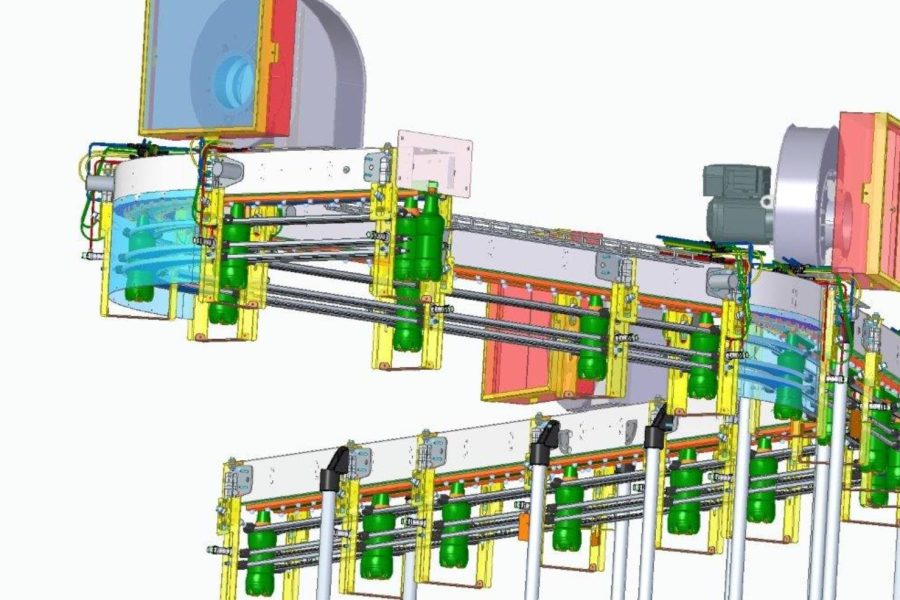

The bottles are moved using the air stream generated by radial fans. The air stream goes to the air channel and next it is directed to the slides which transport the bottles. The speed of the bottles’ movement can be regulated by increasing or decreasing the amount of air generated by the fan (manually or with an inverter).

The number of fans depends on the line layout and is calculated individually for each project in order to ensure the smooth movement of the bottles and energy savings. On the air conveyor, the bottle is attached by the neck – using a special slide, adapted to its shape and made of special materials.

The air conveyor is equipped with adjustable rails to guide the bottle

The rails hold the bottle in the correct position, prevent it from swinging and blocking to ensure stable transport.

The rails can be adjusted to bottle’s diameter and height to ensure correct work for bottles of various sizes and shapes. In case of changing the bottle format, the rails can be adjusted manually or using pneumatic actuators.

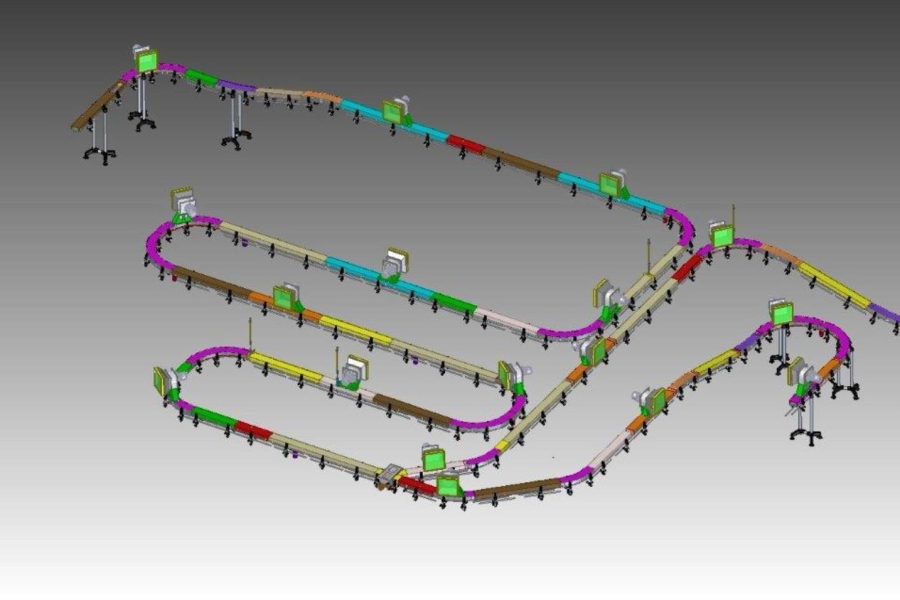

Conveyors offered by SMF are built of easy-to-assemble module

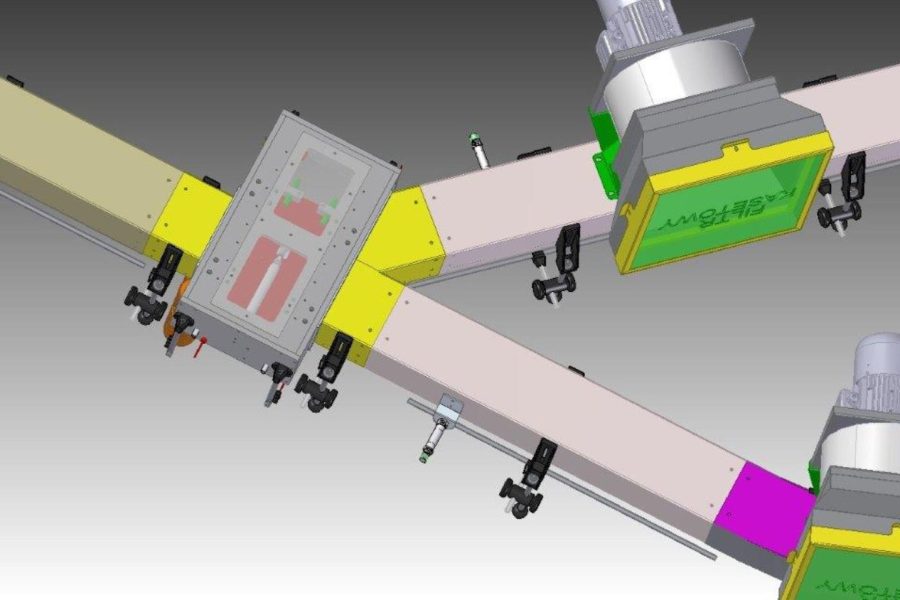

The number and type of modules (straight sections, bends, inclines, slopes) as well as the method of mounting the transporter (on legs, suspended from the ceiling, attached to the walls), the number of fans and the type of execution (standard, special, ultra clean) is tailored to the individual requirements project. The entire conveyor system is connected into one unit, which is operated by a control box (electric box). This system is also equipped with the sensors that enable the exchange of signals between machines in the line and the coordination of their work. In addition, the conveyor system can be equipped with an adder or divider (to connect or divide the bottles for subsequent transporters), with an elevator (to adjust the height of the conveyor) or the so-called a drop gate that allows you to remove the excess number of bottles.

Summary

In a situation where there is a need for the higher level of the hygiene, it is possible to make the air conveyor as ultra clean version. In this version, the entire conveyor has a polycarbonate housing and, additionally, air filters are installed on the fans.

The transport of bottles in the ultra clean conveyor takes place in a closed environment. In order to prevent contamination from penetrating from the outside, a slight overpressure is additionally generated inside the conveyor. The bottles are moved by blowing filtered air, which prevents secondary contamination from the outside.

Reviews

There are no reviews yet.