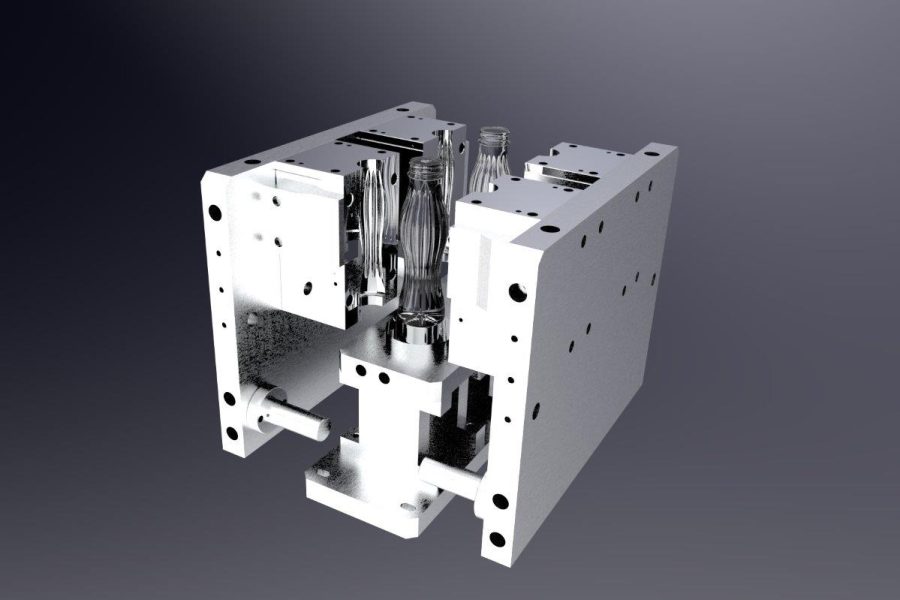

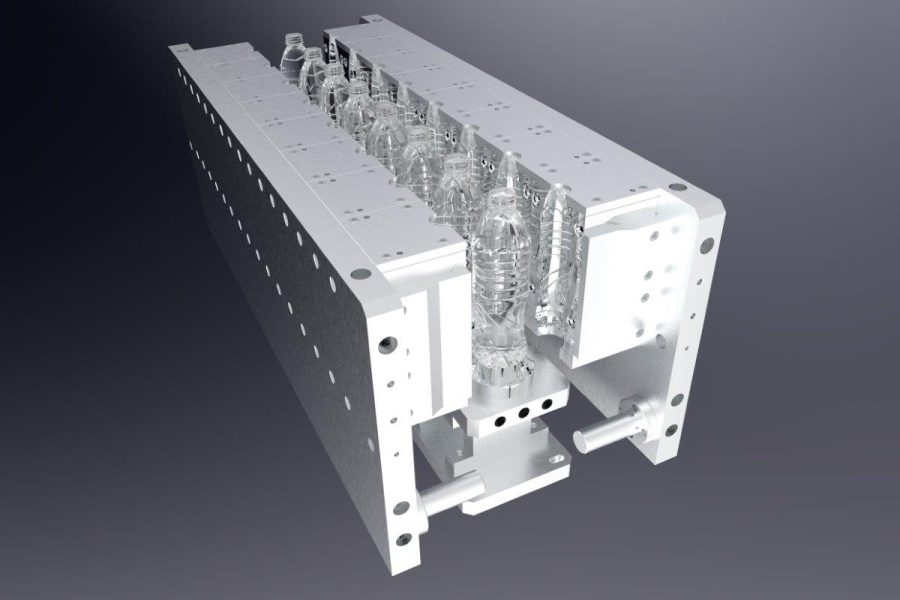

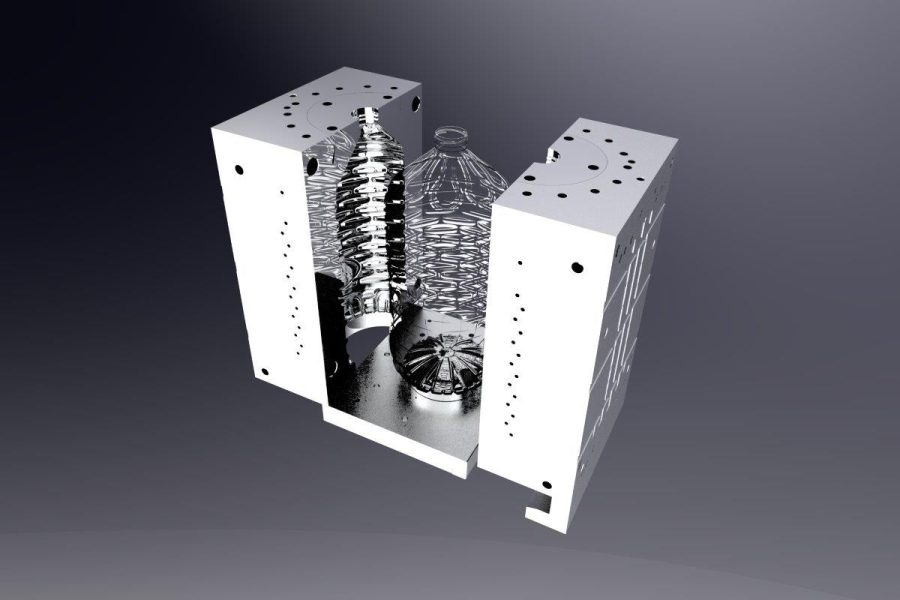

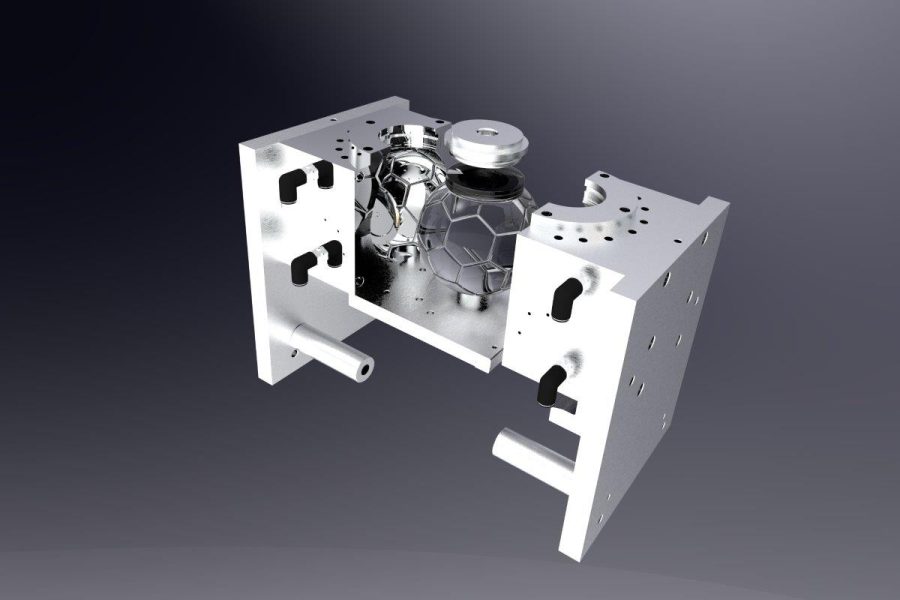

PET blow molds

Customized solutions: PET bottles – blowing molds

Design of the bottle shape has to be customized to the buyer’s needs & market requirements.

Product packaging is not only the packaging as such but also:

• it is also one of the key tools of the marketing of the product

• it is also part of the product’s total cost so it affects final price

• it has to be also convenient storage, handling and logistic

• it has to be durable during transport

Design of PET bottles and more

SMF designers will help you to develop best concept for the bottle design which ensure perfect presentation of your product and has got all key features of perfect packaging. Not only we can make design for the PET bottles, but also we produce complete blowing molds – either for new projects or old SMF blowing machines – any time you need refresh visual presentation of your product or you want add new products to you product’s range.

Share with us your ideas and we will help you to make it true. We will provide you solution for your PET bottles so it can be successfully produced on SMF blowing machines.

New concept for PET bottles & new blowing mould

Works on new concept for PET bottles & new blowing mould is divided into following steps:

• Develop, together with the customer, concept of optimal bottle shape.

• Selection of best preform available on the market (shape, weight, supplier).

• Bottle shape design – making drawings of the bottle with its visualization and dimensions.

• Preparing corrections of the bottle project in references to customer’s remarks, preparing of subsequent versions of the bottle drawing according to the customer’s remarks, up to the development of a design that meets the customer’s expectations.

• 3D model the blowing mould -with the possibility of 3D bottle printing.

• Final acceptance of the bottle design.

• Preparing 3D assembly drawing of a complete blowing moulds including all parts needed to install mould on the machine and ordering special type of aluminum according required dimensions

• Writing a program for CNC machines that will allow to accurately reflect the shape and dimensions of bottle in accordance with the approved drawing.

• CNC production and hand polishing of all components.

• Assembling the mould .

• Tests of the blowing moulds on the blowing machine.

• Verifying dimensions of the physical bottle’s samples with dimensions given on the drawing accepted by the client, including verifying filling level.

• Approval of the blowing mould as compliant with agreed requirements.

Reviews

There are no reviews yet.