Selected:

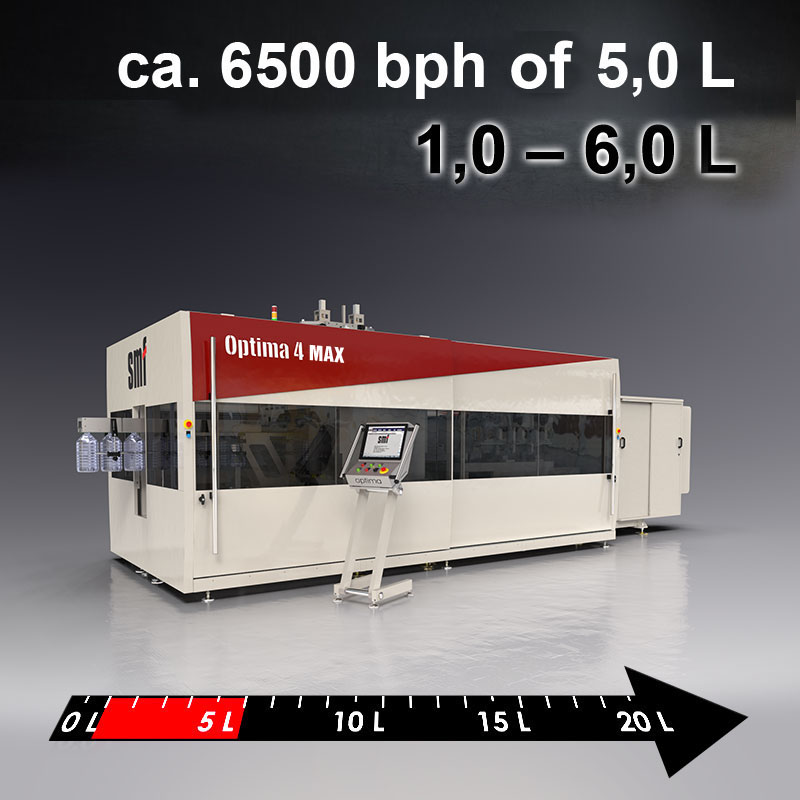

Optima 4 MAX

Product

Social Media

News

JOIN US AT GULFOOD MANUFACTURING IN DUBAI

Welcome 07-09 November 2023 to the Dubai World Trade Center

Starting a Water Distribution Business: 6 Tips You Need to Know

Want to get into the bottled water sector? Looking into

Contact us

- SMF Maschinenfabrik GmbH

-

Stuifenstraße 59,

D-74385 Pleidelsheim,

Germany - +49 7144 888 27 55

- info@smfgmbh.com

- SMF Technology Poland

-

Elektryczna14-16,

21-045 Swidnik,

Poland - +48 81 751 21 04

- info@smfgmbh.com

© 2021 All rights Reserved.

Web by blatni.pl

Reviews

There are no reviews yet.